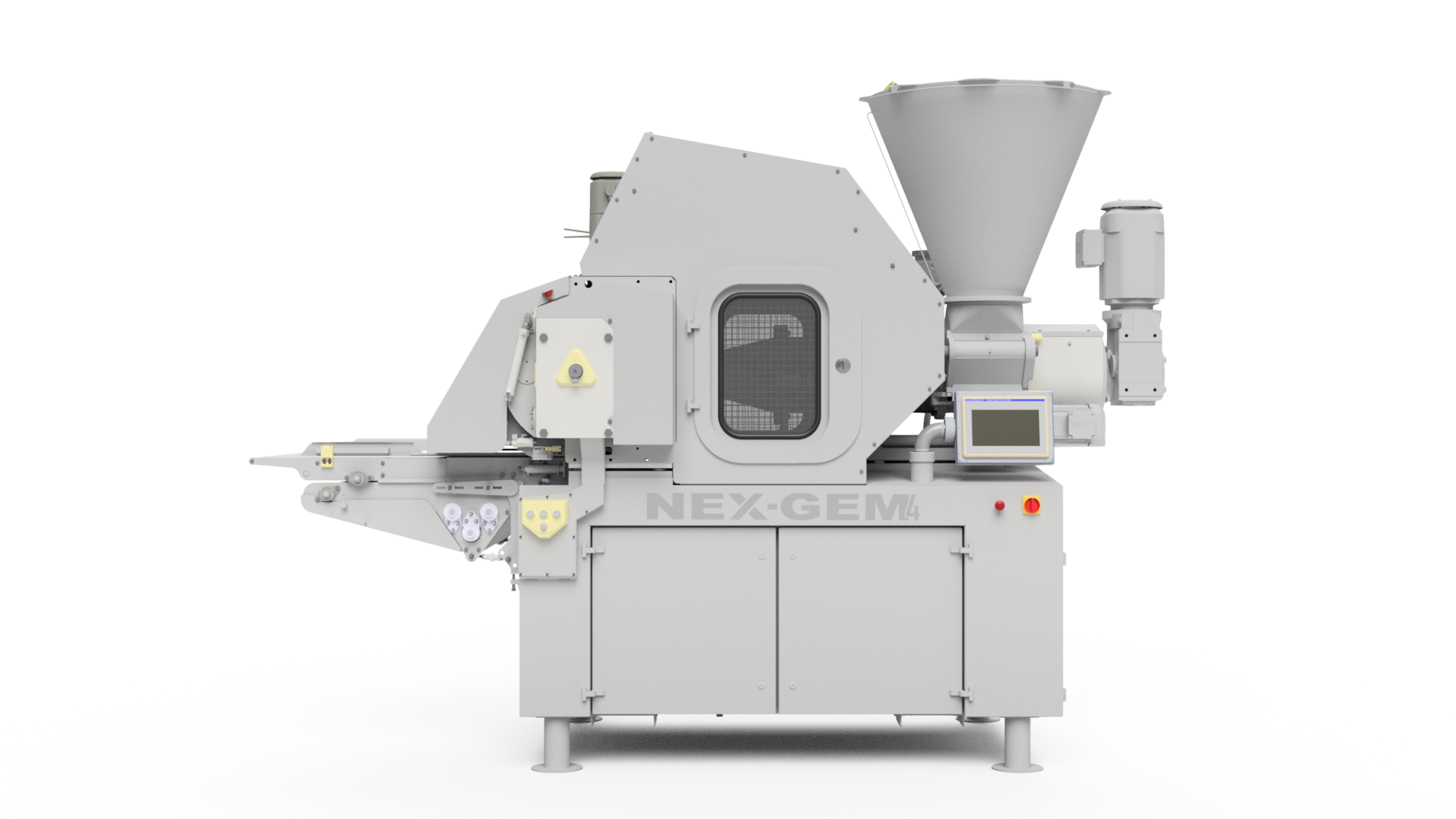

Nex-Gem 4: Built on Legacy, Designed for the Future

________________________________________________________________________________________________________________________

Introducing the New and Improved Nex-Gem 4

At Idaho Steel, innovation, quality, and service have always been at the heart of what we do. That’s why we’re thrilled to introduce the latest iteration of one of our flagship products—the Nex-Gem 4. This evolution represents the perfect balance between time-tested features and cutting-edge upgrades designed to enhance food production efficiency, safety, and quality.

Our customers have long relied on the Nex-Gem series for consistent performance and dependable results. With the Nex-Gem 4, we’re taking things to the next level, incorporating customer feedback and advanced technology to deliver a machine that meets today’s demanding production standards.

What’s New in the Nex-Gem 4?

The Nex-Gem 4 builds on the trusted features of its predecessor while offering several important upgrades that set it apart:

- Simplified Straight Feed

A streamlined feed system ensures smoother operations, minimizing downtime and boosting overall efficiency.

- Dependable Locking Transition

Designed for increased reliability, the locking transition mechanism provides enhanced stability and consistency during production.

- Compact Body Design

The new, more compact design saves valuable floor space while maintaining the same high performance customers expect.

- Upgraded Door Seals

Improved seals offer superior containment, reducing contamination risks and enhancing cleanliness.

- Increased Production Capacity

- Standard: Barrel with 10 rows.

- Optional: XL 5” shape barrel with 8 rows for even greater capacity.

- Advanced Monitoring

Integration with the production line and trend tracking capabilities provide real-time insights, helping operators optimize performance and improve yield.

- Feedback Lighting System

Internal RGBW lighting and an advanced warning system keep operators informed of machine status at a glance, improving safety and reducing potential downtime.

Legacy Features You Can Still Count On

While we’ve added numerous enhancements, the Nex-Gem 4 retains the features that have made it a trusted choice for food producers worldwide:

- ISP Total Control System: Now with an intuitive HMI experience that feels app-based for ease of use.

- On-the-Fly Weight Adjustment: Make thickness adjustments during production without stopping the machine.

- Quick Change Product Shapes: Easily switch between shapes with the proven quick-change system, allowing for a maximum product width of 4 inches.

- Wash-In-Place (WIP) System: The self-contained system with WIP staging ensures complete openness for thorough cleaning.

- Fully Enclosed Unibody Design: Promotes safer, cleaner operations by containing the process environment.

Why Choose the Nex-Gem 4?

With the Nex-Gem 4, Idaho Steel continues to push the boundaries of what’s possible in food production. Whether you’re looking to upgrade your current facility, expand your product line, or test the market with a new offering, the Nex-Gem 4 provides the flexibility, reliability, and performance you need to succeed.