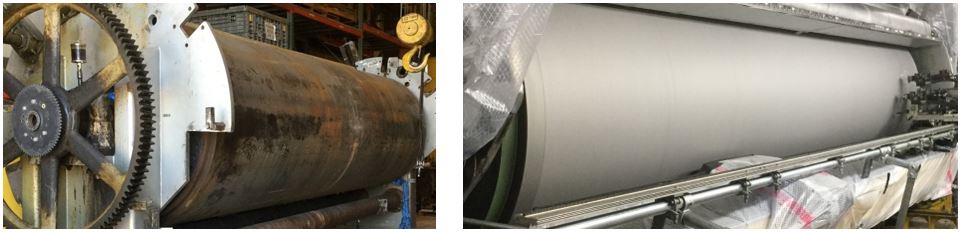

Profile grinding requires precise equipment and experienced technicians. With more horsepower and a more stable base we can remove stock more accurately and faster than any other machine today. Our advanced contact wheel design, custom belts and true tangential grinding will also help reduce your down time.